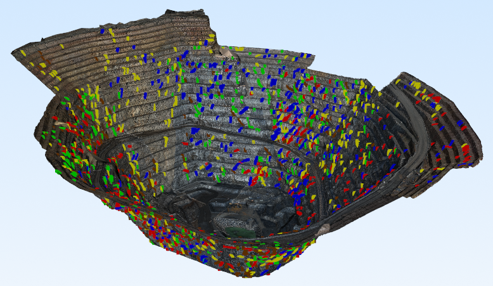

Open-pit structural mapping and geotechnical analysis

Traditional open-pit face mapping is slow (typically 1–3 days per face), highly subjective, and largely descriptive, with limited predictive capability, often leaving critical risks such as weak structural zones or water-conducting features unidentified until after exposure.

To address these limitations, we develop an automated workflow for open-pit face point cloud processing, integrating geometric normalization with feature extraction using a dual-head Plane + Trace fusion model. This approach enables the rapid generation of design-ready fracture sets and trace maps within ≤2 hours per face, achieving ≥95% identification accuracy.

Through continuous, rolling data fusion across successive excavation stages, look-ahead 3D discrete fracture network (3D-DFN) models are constructed, providing quantitative outputs including fracture orientations, connectivity indices, and localized geotechnical risk hotspots.

These results directly support pre-operational decision-making, such as blast design optimization and slope stability control, effectively shifting geological work from post-event analysis to pre-event prediction.

The framework has been validated in multiple operating open-pit mines, demonstrating tangible improvements in slope safety, resource recovery, and operational efficiency, with overall cost reductions exceeding 25% compared to mainstream commercial software.

An auditable workflow, covering data lineage, model versions, and parameter traceability, further ensures robustness and compliance for engineering review and safety audits.